1. Испытание обуви на сопротивление скольжению

(1) Тест на рампу

Стандарты: EN ISO 13287, DIN 51130.

Процедура:

Испытательная платформа: Регулируемый наклонный пандус (0°–35°),

поверхность, покрытая стандартными испытательными материалами (например, керамическая плитка, стальная пластина + раствор глицерина для имитации влажных и скользких условий).

Испытатель надевает образец обуви и постепенно увеличивает угол наклона платформы до тех пор, пока не произойдет скольжение.

Критический угол: запишите угол, под которым подошва начинает скользить (чем больше угол, тем лучше сопротивление скольжению).

Классификация классов:

DIN 51130: делится на три класса (A, B, C; класс A — самый высокий, подходит для маслянистых промышленных сред)

EN ISO 13287: Минимальный критический угол ≥12° (сухая поверхность) или ≥8° (влажная поверхность)

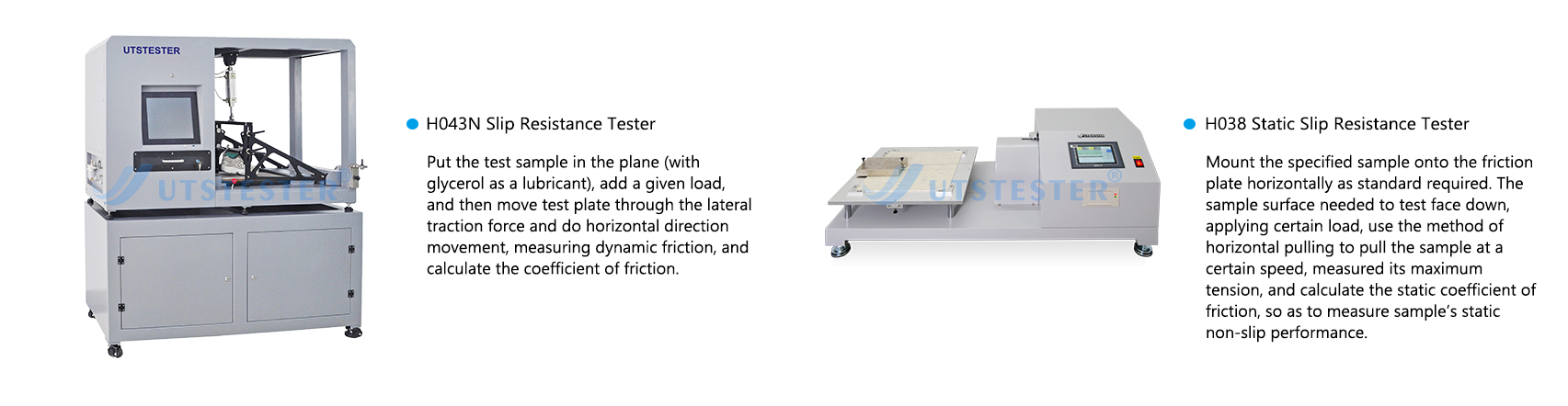

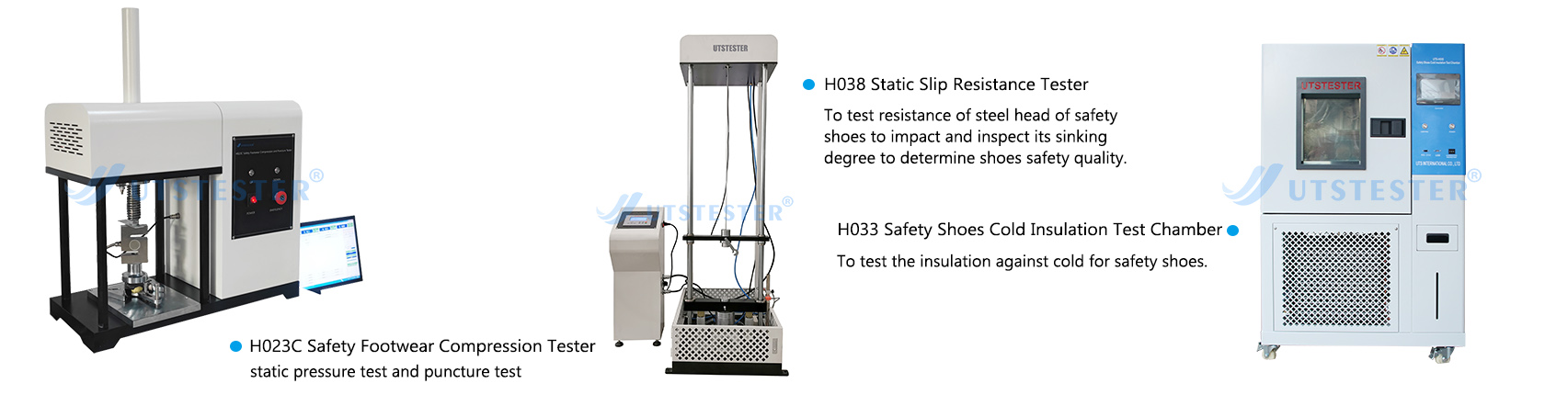

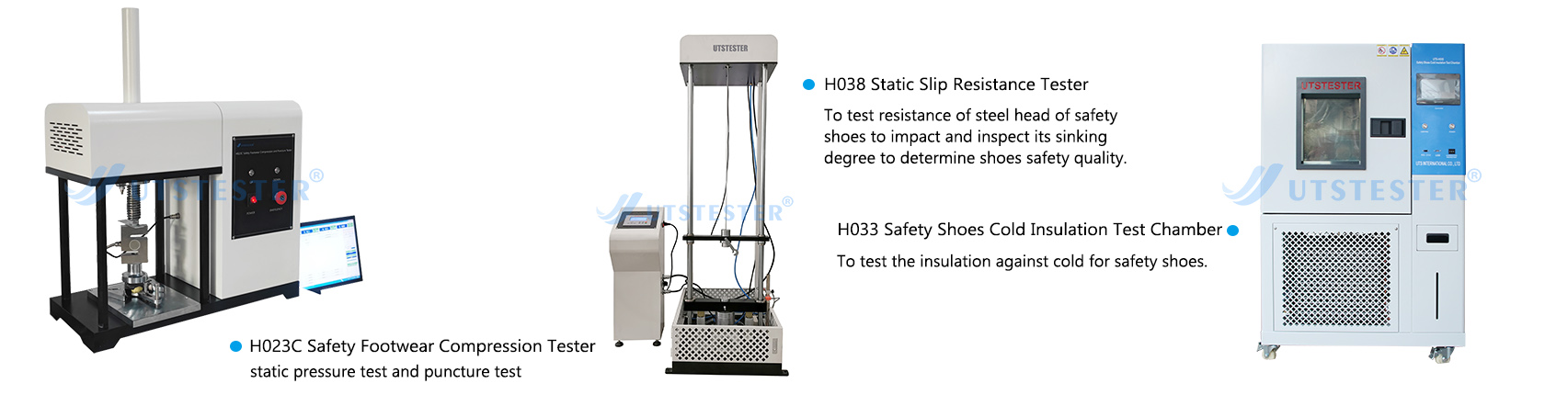

(2) Метод испытания коэффициента трения (

тестер трения

метод)

Стандарты: ASTM F2913, GB/T 3903.6

Шаги:

Контактная поверхность: сухое/влажное/масляное состояние;

Давление: Имитация давления стопы человека (например, 50 Н)

Оборудование:

Маятниковый или тяговый испытатель трения,

имитация динамического/статического трения между подошвой обуви и землей

Параметры теста:

Результаты: Рассчитайте статический коэффициент трения (COF) и динамический коэффициент трения (обычно требуется COF ≥ 0,4).

2. Испытания безопасности обуви

(1) Испытания на удар и сжатие. Основная функция защитной обуви — защита стоп от травм, вызванных ударами и сжатием. Стандарт EN ISO 20345:2022/A1:2024 требует, чтобы защитная обувь выдерживала ударную энергию не менее 200 джоулей (эквивалентную падению 20-килограммового предмета с высоты 1020 миллиметров) и сжимающую силу 15 килоньютонов (кН) (эквивалентную 1,5-тонному весу, приложенному к носку).

Методы тестирования:

Ударная прочность: Ударный молоток определенного веса (например, 20 кг) падает с определенной высоты (например, 30 см) на носок ботинка и измеряется деформация носка ботинка (должна быть ≤15 мм) при отсутствии острых краев или трещин внутри носка ботинка.

Сопротивление сжатию: приложите вертикальное давление (например, 15 кН) к носку ботинка с помощью пресса, удерживайте в течение 1 минуты и проверьте наличие деформации и структурной целостности носка ботинка (отсутствие трещин или чрезмерной деформации).

Эти два испытания имитируют риски травм от ударов тяжелых предметов и сдавливания в реальных производственных условиях для оценки защитных свойств спецобуви.

(2) Испытание на стойкость к проколам Испытание на стойкость к проколам является критически важным показателем для оценки способности межподошвы защитной обуви противостоять проникновению острых предметов. Стандарт EN ISO 20345:2022/A1:2024 содержит подробные спецификации для испытания на стойкость к проколам, включая методы испытаний как металлических, так и неметаллических прокладок, устойчивых к проколам. Для металлических прокладок, устойчивых к проколам, стандарт требует не более 3 точек коррозии со средней площадью не более 2 мм²; для неметаллических прокладок, устойчивых к проколам, таких как композитные материалы (типа PL и PS), стандарт требует отсутствия проколов после нескольких испытаний и отсутствия разделения слоев.

Метод тестирования:

Закрепите образец подошвы и проткните его вертикально стальным гвоздём диаметром 3 мм с заданной скоростью (например, 50 мм/мин), регистрируя максимальную силу в момент прокола (которая должна быть ≥1100 Н, а некоторые более высокие стандарты требуют ≥1500 Н). Некоторые модели защитной обуви могут иметь стальные пластины или кевларовые волокна, встроенные в подошву, и испытания должны подтвердить их защитную эффективность.

Электронная почта:

hello@utstesters.com

Прямой звонок: + 86 152 6060 5085

Тел.: +86-596-7686689

Веб:

www.utstesters.com

+86 152 6060 5085

+86 152 6060 5085

English

English русский

русский español

español português

português

hello@utstesters.com

hello@utstesters.com hello@utstesters.com

hello@utstesters.com +86 152 6060 5085

+86 152 6060 5085 +8615260605085

+8615260605085